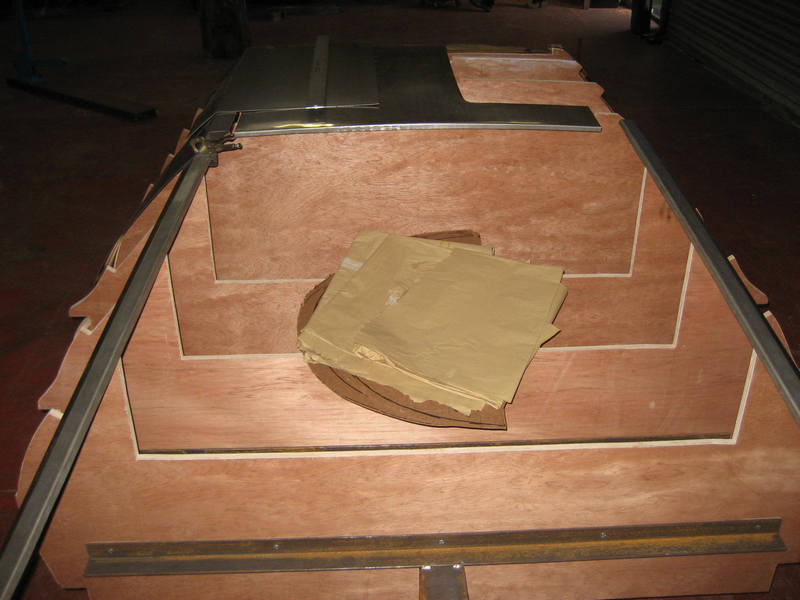

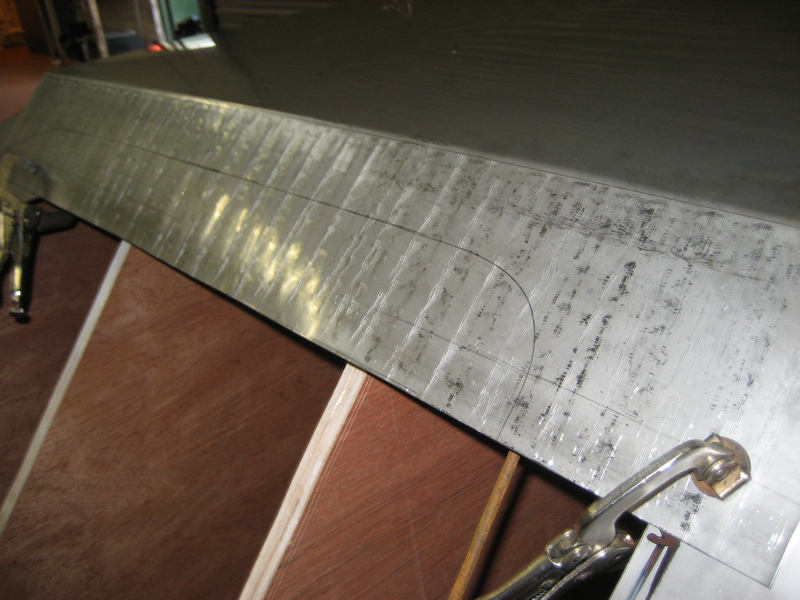

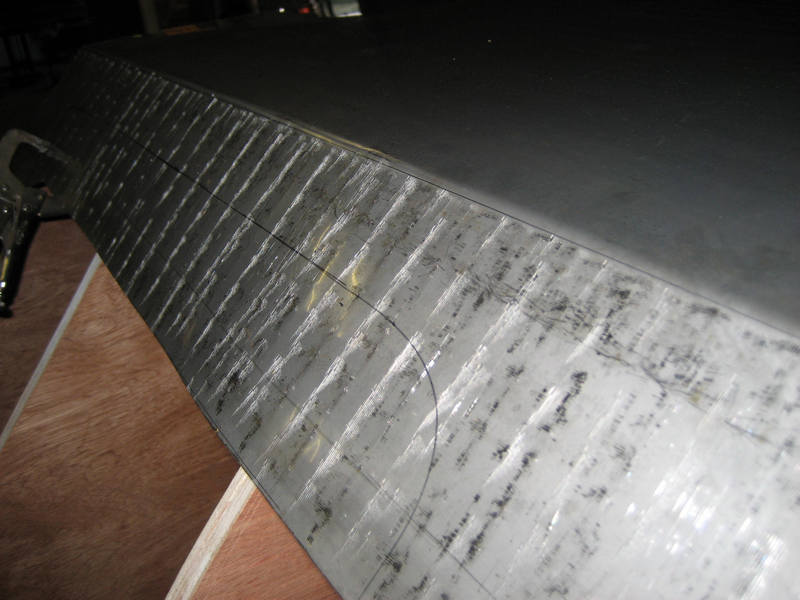

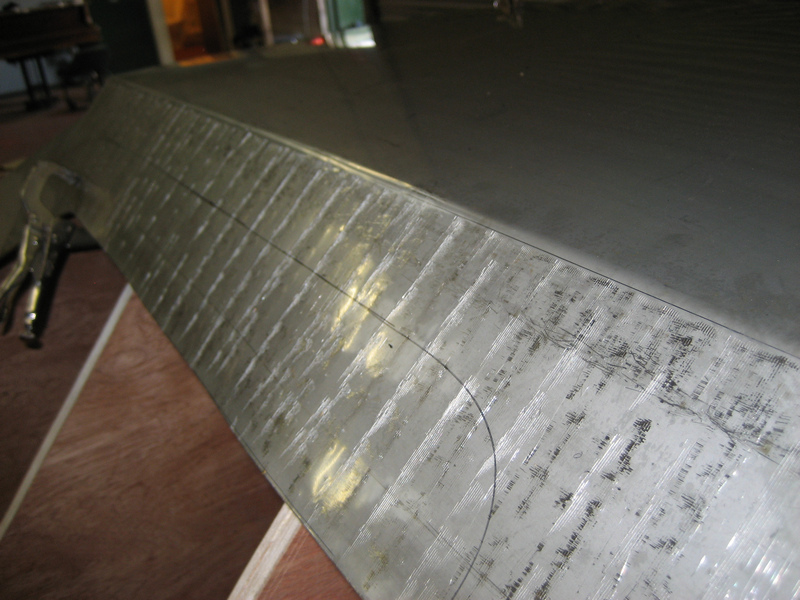

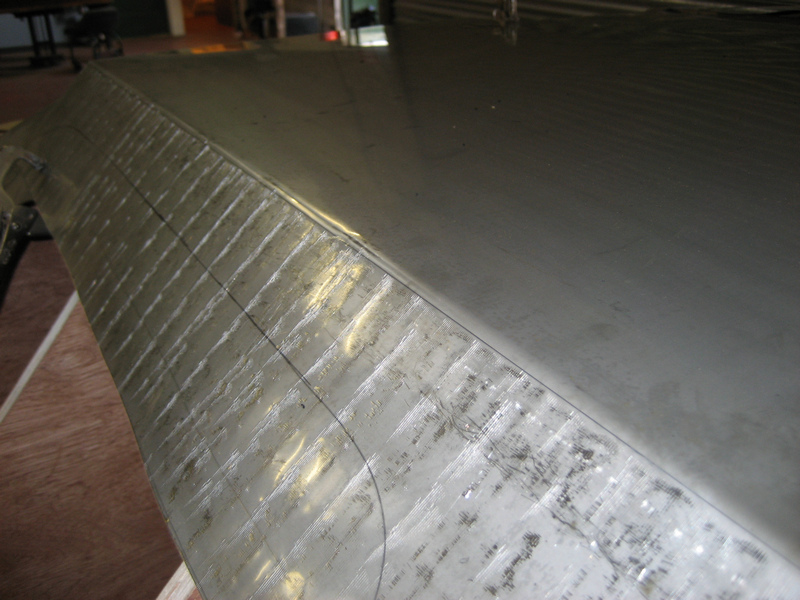

Stainless Steel Fabrication Part 1

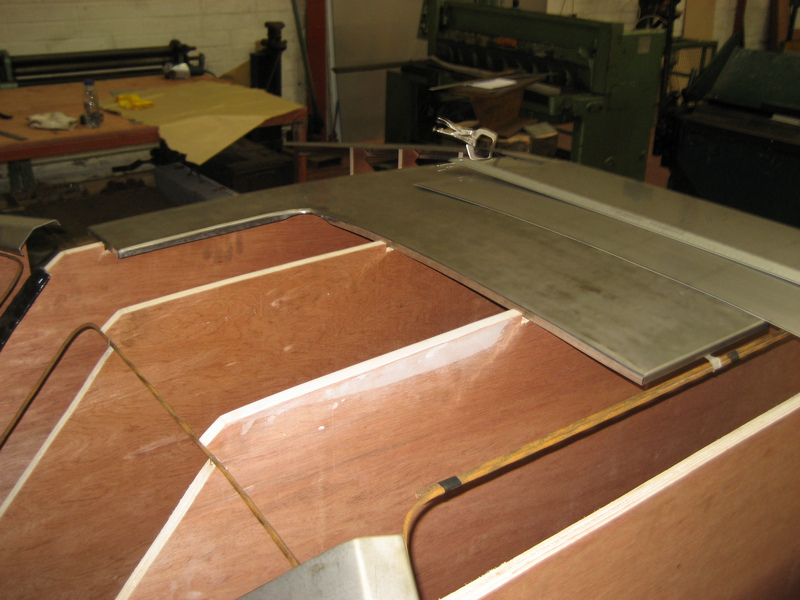

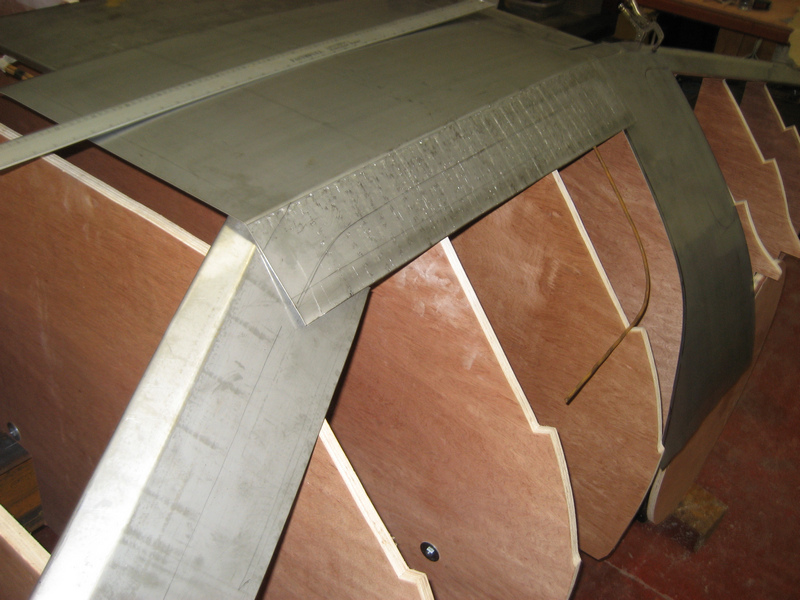

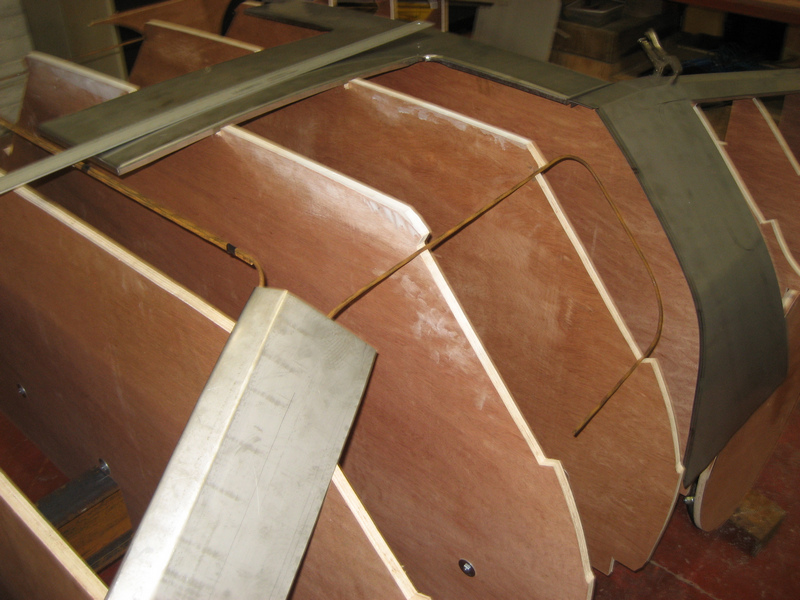

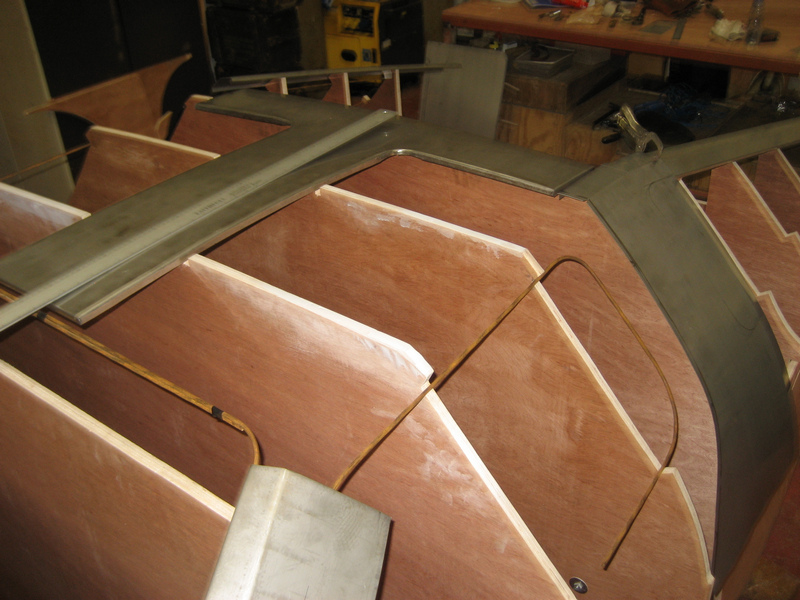

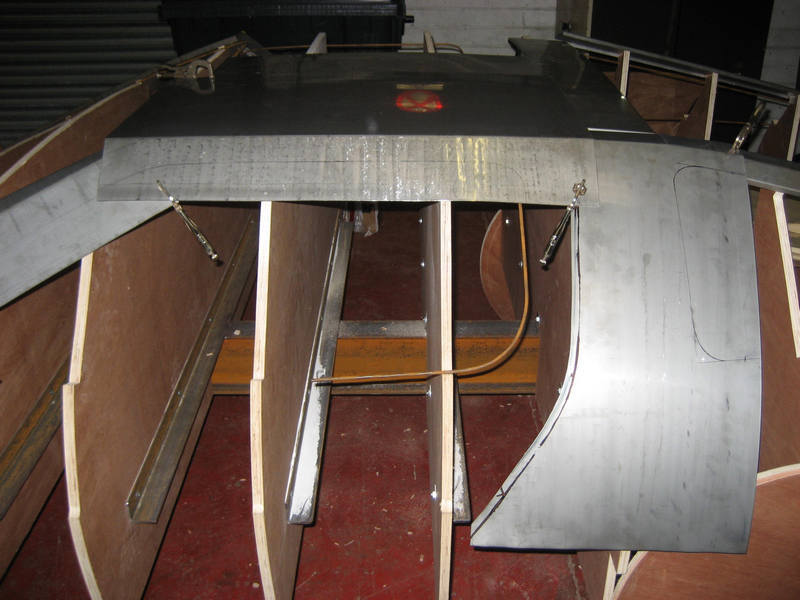

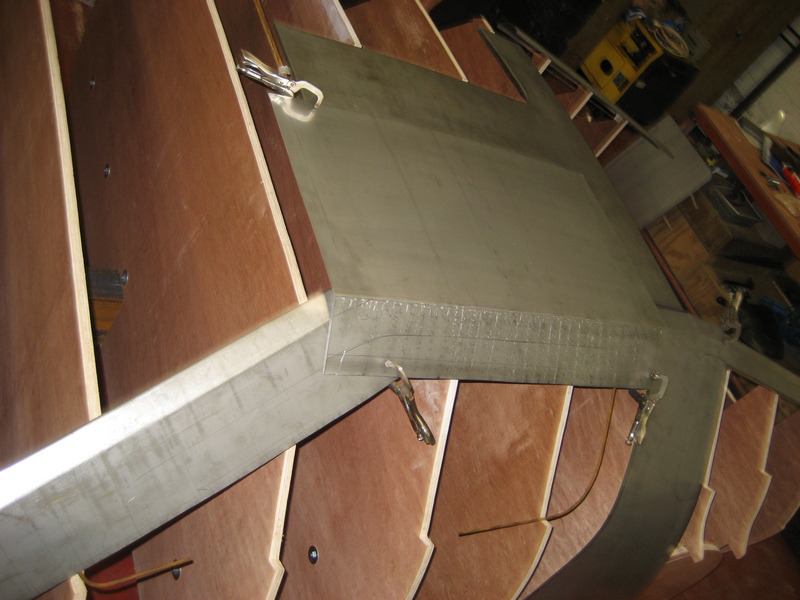

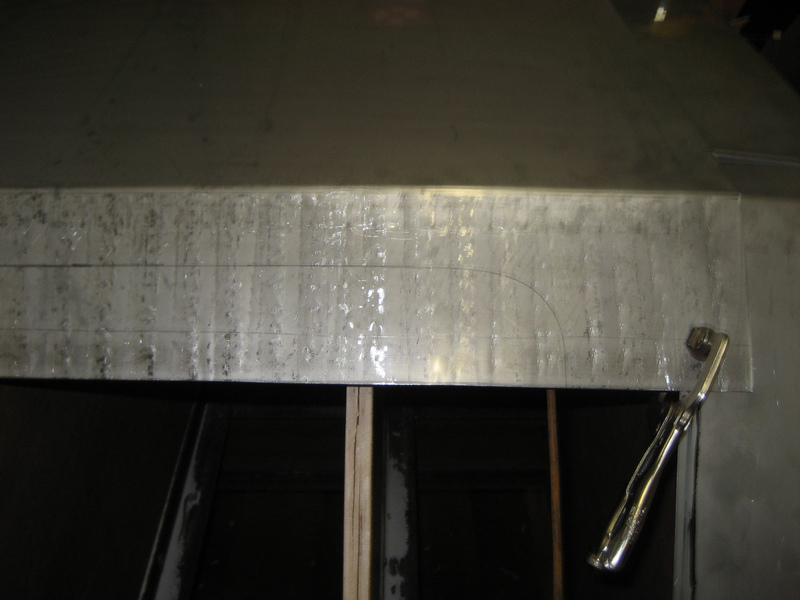

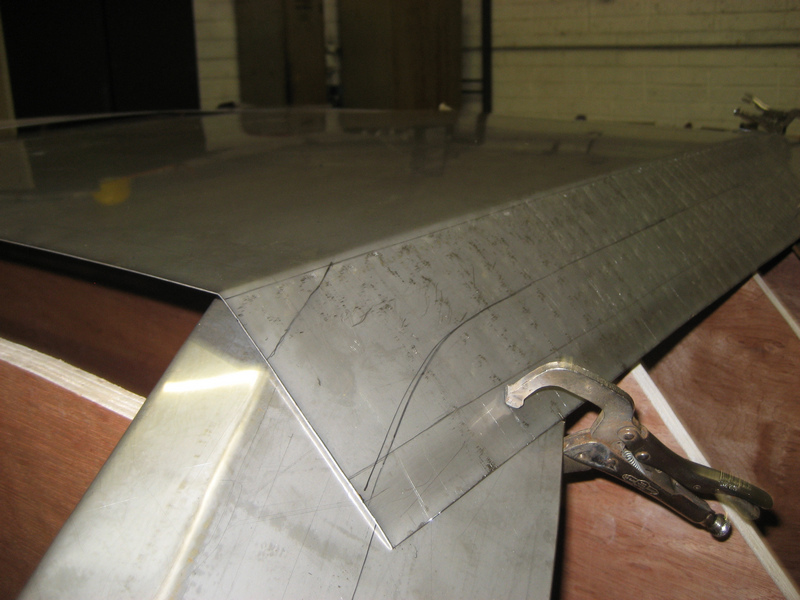

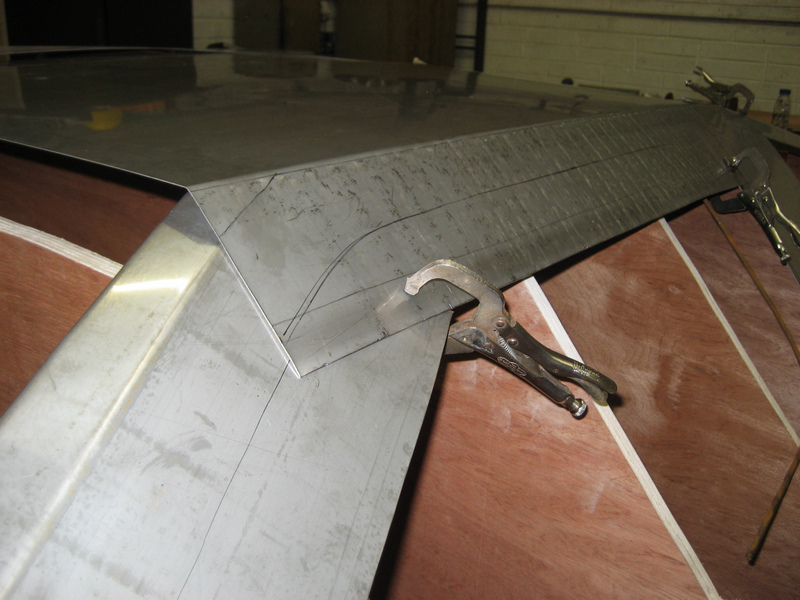

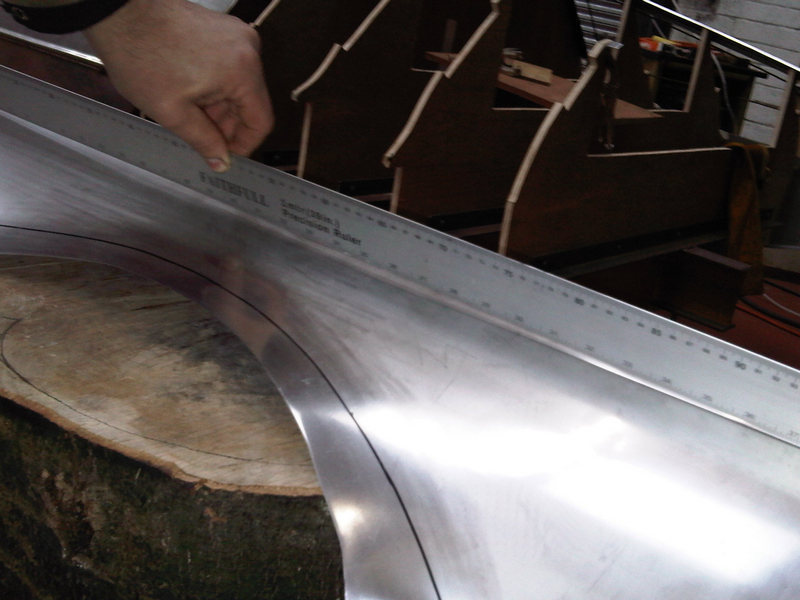

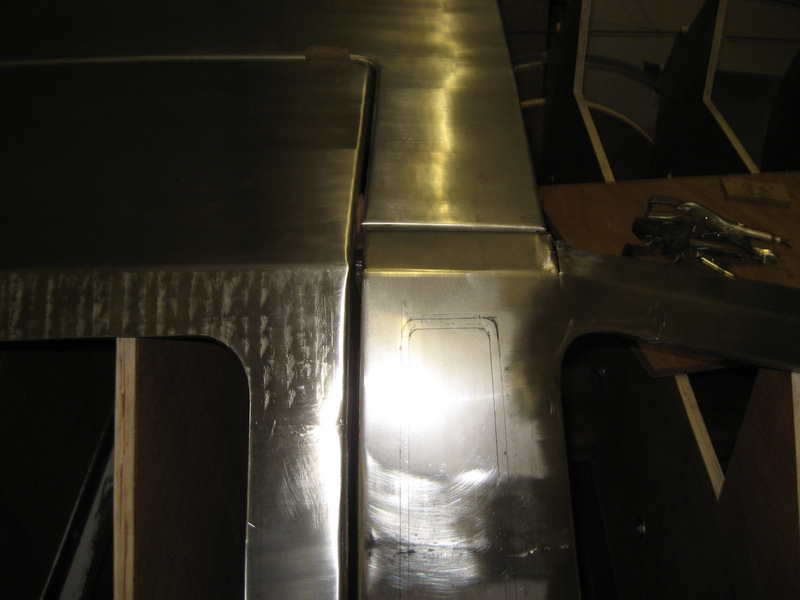

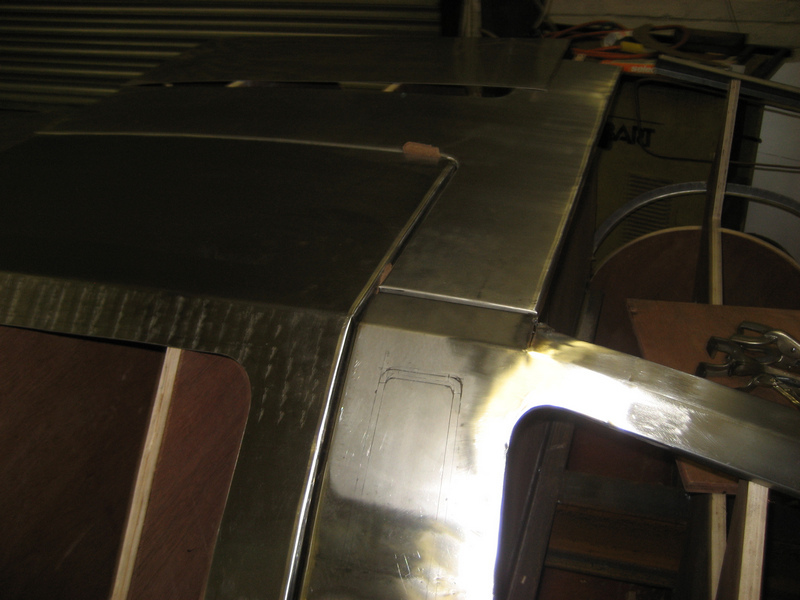

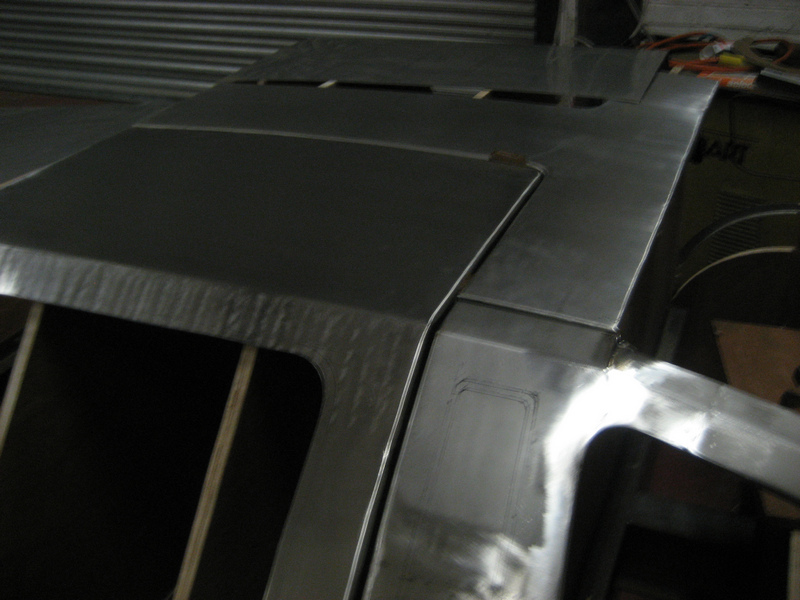

Now onto the first set of pictures showing how Neil formed the stainless steel (SS304) bodypanels by hand. Pictures speak a thousand words, which means there is the equivalent of 167,000 words of information below! So I'll keep the text short and just share some details which Neil told me - he used a swage and made a flypress tool to form the crease which runs along the side of a DeLorean body, just above where the black rubstrip would be.

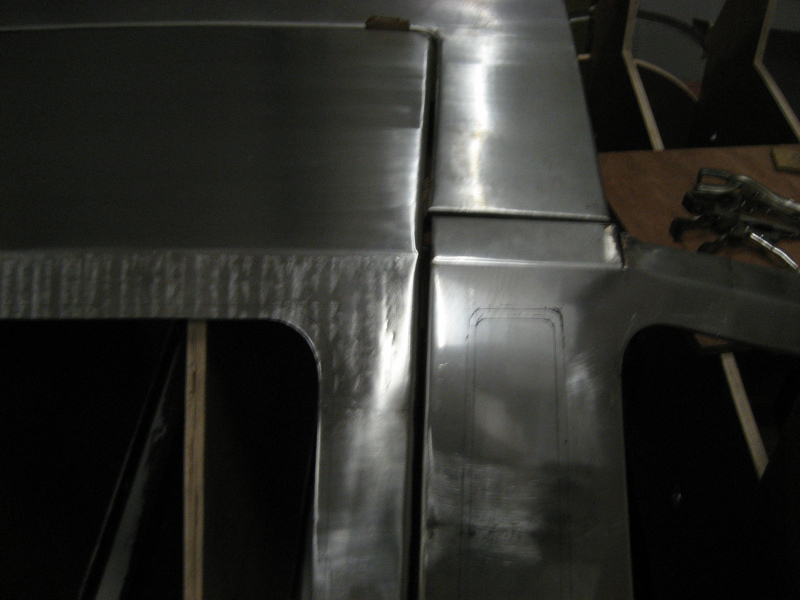

As you can see below, panels were formed in sections and welded together. They were but-welded below the swage line, using TIG welding with an SS304 rod.

Flanges were either thrown by hand with hammer & dolly, or turned with a swaging machine.

2 attempts were made at creating the bonnet/hood - so you will see the evolution of this throughout the pictures on this page and the next. The first bonnet had too deep a swage line, which ended up destroying the panel shape. So on the second bonnet, Neil used a Jenny Swage and did a double run.

Enjoy the pictures!

More pictures of the metalwork on the next page!